N A ROTO MACHINES AND MOULDS INDIA

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to N A ROTO MACHINES AND MOULDS INDIA

Pulveriser For Rotomoulding

Application

Typical applications of LPU pulverisers are the grinding varieties of granulated material including high and low density plastics like: LLDPE (Reliance : 36RA 0345 & R35042, Sabic : R 50035 & M500026, IOL : 042R35A, HALENE-L : 73004T & 73005T, EL-LENE : M3804RU/RUP & M735RW/RWP, G-LENE : R35A042 ), LDPE (16 MA 400 IPCL grade for textile and wire coating), LLDPE, HDPE (26500 Reliance grade for master batch), RPVC, EVA, etc.

With the support of In-House R&D, we are pioneer in the field of manufacturing Pulveriser Machine with proven technology. More than 700 Nos. Pulveriser Machines are successfully running all over the world.

Extruder For Colouring Or Compounding And Recycle

Feature

Cold start protection

Microprocessor based machine Control Panel with Digital Display

Good Quality compounding

Synchronized control for pelletizer to avoid over feed or under feed strand to the pelletizer

Heaters are fully enclosed to ensure protection and safety

Air knife for moisture free strands and efficient cooling of the strands and pellets (on request)

Pneumatic hopper loader (on request)

Scrap Grinder For Scrap

Heavy mild steel structure with hopper for easy loading of scraps. Unique design of rotor blades functioning as shredding is our unique design. Sturdy multiple rotory and fix blades of alloy steel for longer services life and efficient grinding. Option for material conveying system after grinding.

Scrap Cutter

Description / Specification of Scrap Cutter

We are involved in offering a wide range of Scrap Cutter to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Scrap Cutter. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

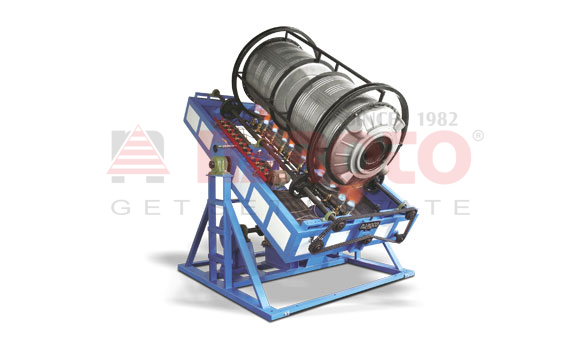

Mixer For Granule And Powder Mixing

High efficient high speed Mixer designed to generate heat due to friction. The high speed Mixers are used to mix granules with pigment paste or pigment powder or different colored granules for uniform blending.The high speed mixer achieves heat while working is important to blend the pigment paste and polymer powder uniformly.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.